Paddington Exchange

Paddington Exchange, North Wharf Gardens – 150 stunning apartments to the heart of Paddington

The building has 3 towers which step up to a maximum height of 14 storeys towards the Regent’s Canal. The development provides 1, 2, 3 and 4 bedrooms apartments, a combination of private and public amenity space, along with roof terraces and private balconies.

The Challenge

Paddington Exchange, designed by Powell Dobson Architects and Assael Architecture, was designed to create maximum light to these stunning Taylor Wimpey Central London apartments. Powell Dobson commented on their vision for the balconies and terraces, “structural glass balustrades create glamorous appeal from the outside, while allowing uninterrupted views out to the London skyline.”

With the balustrade being an integral part of the architectural vision, this BIM Level 2 project presented a number of initial design challenges:

- The handrail for the vertical bar balustrade needed to be fixed behind the brick slip facade to achieve the necessary balustrade loading.

- The balustrade to some of the terraces had to be fixed to a very small 100mm wide concrete upstand.

- There was to be a phased project handover creating programme challenges.

The Solution

BA Systems were contracted by Bouygues UK to deliver balustrade solutions to the inset balconies, terraces and stair cores on this prestigious development.

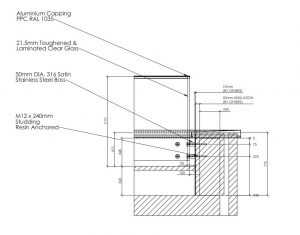

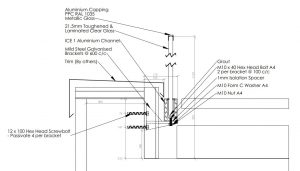

For the inset balconies and terraces, where glass balustrade was required, the B40 Frameless balustrade product was proposed. To accommodate varying upstand heights, two fixing details were designed. On the terrace areas were the parapet wall provided a fixing surface, the boss fixing option was utilised (fig. 1). Where the fixing details had to be concealed beneath the finished floor level, the BA Systems design team developed a galvanised steel bracket to offset the ICE 1 channel from the upstand (fig. 2).

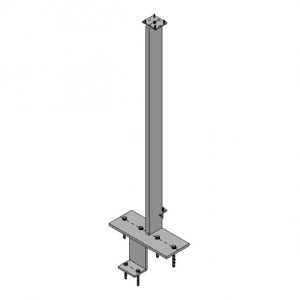

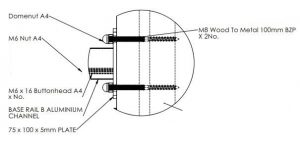

To complement the brick facade, a vertical bar balustrade was required for some inset balconies. BA Systems proposed the B30 Frame and Infill balustrade. In order to create a sturdy solution that met loading regulations, the BA Systems design team developed 2 bespoke fixing options for the balustrade. In some areas there was only a 100mm wide upstand to fix to, so a bespoke ‘stepped’ steel post was developed (fig. 3). In other areas, a bespoke steel plate was used to fix our B30 handrail through the brick slip facade into the steel windpost.

On the stair cores, the B20 balustrade with a satin stainless steel handrail and glass infill was complemented with the 42mm diameter stainless steel B10 handrail.

In order to protect the balustrades on site and ensure a quality finished product for hand over, BA Systems wrapped posts and handrails prior to delivery from our manufacturing facility (fig. 5).

Project Achievements

-

Hand over

Balustrades on each block were handed over in stages to accommodate the building control sign-off

-

Agile delivery

The BA Systems operations placed early stock orders to ensure that operations would remain flexible to the changing completion dates.

Contractor Testimonial

BA Systems responded well to the design challenges and were flexible to the demanding programme requirements. The finished product looks good with the brick and stone façade.

Fadi Alabed, Project Manager