Moberly Leisure Centre & Kensal Rise

Moberly Leisure Centre and Kensal Rise – A mixed-use Westminster development that delivers over 100 homes, shops, restaurants, bars and a leisure centre.

EcoWorld London, the developers behind the mixed-use Kensal Rise scheme, have worked in partnership with the Westminster City Council to cross-fund the leisure centre. The apartments and four-bed townhouses are built around the Moberly Leisure Centre.

The Challenge

The project was designed by Roberts Limbrick Architects and constructed by Willmott Dixon. The mixed-use nature of the development meant that there was a wide variety of demands on the balustrade solutions.

For the leisure centre, a solution was required that withstood the high footfall in the main atriums and stair cores. Additionally, the balustrade product needed to reflect the modern and sleek nature of the leisure centre design.

On the Kensal Rise townhouses, a timber construction provided some challenges for the balustrade fixing detail. The balustrade base channel had to be elevated by nearly 500mm to ensure the channel finished flush with the finished floor level.

Project Achievements

BA Systems were contracted by Willmott Dixon to provide the B20 Balustrade with heat soaked glass and the B10 Wall Handrail to the main stair cores and voids in the leisure centre. For the townhouse terraces, the B40 Frameless Glass Balustrade was chosen. This system utilised 21.5mm toughened and laminated glass and was accompanied with a low profile 27x28mm polyester powder coated capping handrail.

-

Crowd Loading Balustrades

On the level return at the top of the main stair, a 3kN/m balustrade loading was required to accommodate the potential for crowds in the area. To ensure compliance, the BA Systems team redesigned the B20 system with 60mm diameter satin stainless steel posts with internal mild steel supporting spigots.

-

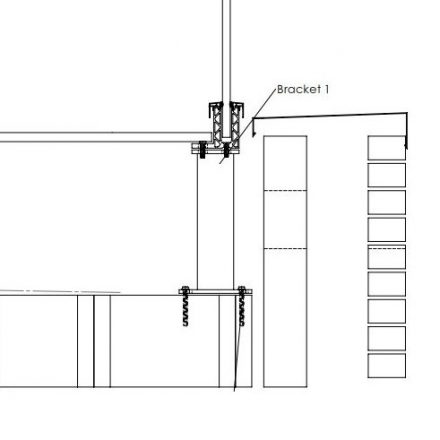

Balustrade Secondary Steelwork

To accommodate the large floor build-up on the townhouse terrace area, the BA Systems design team developed a bespoke galvanised steel ‘I-shape’ bracket. The base bracket was then fixed at 600mm centres to the balustrade base channel. The steel brackets were fixed to the timber joists.