Christopher Boone’s Almshouses

Christopher Boone’s Almshouses – An 88 home redevelopment in Lewisham that primarily delivers new housing for elderly people.

The housing association, One Housing, have partnered with The Merchant Taylor’s Boone’s charity to redevelop this Lewisham site. The project consists of 62 one and two bed Extra Care apartments for elderly people. The remaining 26 homes are being sold on the open market.

The Challenge

The development was designed by PRP Architecture and main contracted by Rydon Construction. The main element of the project was the Extra Care U-shaped building that was constructed around a central courtyard garden. Each flat has its own access door off the central walkways.

The design requirements for the balustrade presented a number of initial challenges:

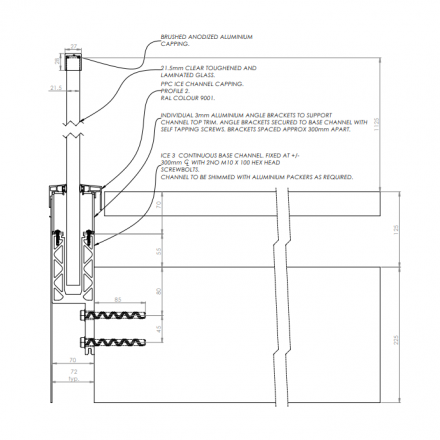

- In some areas, the base fixing detail on the balustrade needed to finish flush with the finished floor level and with the outside edge of the brick fascia. This presented a complexity as the balustrade base fixing would need to be elevated off the concrete slab.

- The handrails on the walkways needed to be warm-to-touch.

The Solution

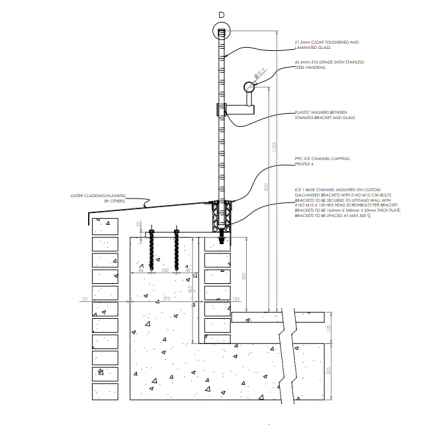

Our final balustrade solution for the project included our B40 Frameless Glass balustrade to the concrete balconies and terraces. We worked closely with surrounding trades, such as the cladding sub-contractors, to provide an aluminium trim product that interfaced with the balcony fascias. On the balconies, we used a small low-profile aluminium capping trim to the top of the glass. For the walkway balustrade we provided a 42mm diameter offset satin stainless steel handrail.

For the internal stair cores, we provided our B20 Post and Glass Infill balustrade. This was complemented with our B10 Wall-Mounted stainless steel handrail. On one stair, this balustrade option was installed to a curved stair flight where a curved handrail was used with faceted glass infill panels.

- 01 – B40 glass balustrade to the balconies

- 02 – B40 glass balustrade to the balconies

- 03 – B40 glass balustrade to the balconies

- 04 – B40 glass balustrade to the terraces

- 05 – B40 glass balustrade to the terraces

- 06 – B20 post and glass balustrade to the stairs

Project Achievements

-

Bespoke trim details

To ensure that the base fixing detail finished flush with the finished floor level, our design team developed some bespoke brackets and trim extrusions to fix on top of the base channel. This also removed the need for any expensive secondary steelwork to elevate the base channel up to the finished floor level.

-

Value engineering

In order to provide value engineered options with compromising the quality of the development, our design team offered a couple of value engineered options. In one area, a curved toughened and laminated glass balustrade was specified. Our solution was to provide faceted glass panels in lieu of the curved glass. For the walkways, a timber handrail was specified. To avoid the challenges of timber weathering in external conditions we provided our stainless steel handrail as a ‘warm-to-touch’ alternative.

-

Bespoke fixing plate

In one area, the base channel for the B40 Frameless balustrade was mounted offset from the concrete upstand. This was to ensure that the balustrade finished flush with front of the bricks. In order to accommodate this design requirement with compromising the balustrade loading, our design team developed a detail where the base channel was fixed to a large 20mm thick steel plate mounted back to the concrete upstand.