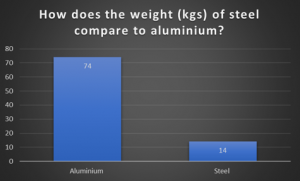

1.Weight

Aluminium is typically about a third of the weight of mild steel. B50 balustrade vertical bars are engineered as extruded components which means that a linear metre of B50 Surface mounted balustrade weighs about 14kg compared to steel which weighs 73.5kgs

- Advantages

- B50 balustrades are easily man handled in transportation and on site.

- The low weight translates into reduced energy consumption in transportation.

- Installation takes place at a much faster pace supporting tight program completion dates.

- Less safety and access risks on site.

- Balustrade panels can be designed in larger sections than mild steel simply because of the weight advantages.

2. Corrosion Resistance

Aluminium is corrosion resistant even without any further surface treatment whereas steel rusts.

- Advantages

- Aluminium can be powder coated or anodised with highly successful and enduring surface protection systems. If the surface becomes damaged or scratched the base metal wont corrode or rust.

- Because of the nature of extruded aluminium the surface finish after powder coating is far superior to that of steel with excellent adhesion properties of the coating to the base metal surface.

- Maintenance is less costly as B50 is mechanically assembled rather than welded mild steel and there is no chance of moisture ingress and corrosion at welded joints.

- For more details on corrosion see the following link to our blog post detailing this topic here

3. Mechanical Assembly

The B50 system is engineered for off-site mechanical assembly with no unsightly welded joints.

- Advantages

- Mild steel balustrades have fully welded joints with potential for weld porosity and pin holes. This leads to water ingress and corrosion of the base metal.

- B50 Aluminium Systems are fully mechanically assembled with secrete fixings and clean lines at the joints.

- For more details on this see our testimonial video from Inland Homes on the following link here

Back to blog