Recent emphasis on bringing all elements of our manufacturing in-house has enabled us to provide more accurate lead times for our projects as we’re in closer control of what we’re producing.

We manufacture over two workshops; we refer to as BA1 and BA2. BA1 is where we predominantly manufacture stainless steel and BA2 is our aluminium workshop. We carry out a variety of processes to ensure our products are made to the best standard and this is only made possible with our highly skilled workshop team who are fully trained in a variety of fabrication processes.

Welding

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. It can be carried out to a variety of materials including plastics and wood. We weld metal and to a variety of joint configurations dependant on the product we’re producing. Welding is used daily in our fabrication process, largely in the manufacture of stainless systems such as Handrails, Wall Brackets, and our Cavity Tray Systems.

Polishing

Polishing metals is of pivotal importance, particularly where materials need protection from external conditions or to lessen the likelihood of rust. Polishing metal is useful for aesthetic reasons as the process enhances the surface quality of the metal. Polishing supports the metal in removing contaminants from the metal surface. Unpolished metal surfaces are full of variations, pollutants, and polishing eliminates impurities not visible to the naked eye, making them less likely to receive the impact of corrosion as it reduces the size of crevices on a metal surface. Sometimes the requirement for polishing is purely for aesthetic reasons specified by the Architect such as a mirror-polished finish. This process is used predominantly for our Handrail Systems.

Bending

As a specialist manufacturer of Handrail Systems, bending is a large part of our fabrication process. Handrails are bent to a variety of angles and specifications, made bespoke to suit each project requirement. We have the in-house machinery to support this process, keeping us in control of what we produce. Tubes can be bent satisfactorily where one end of the straight tube is clamped and the machine former rotates to pull the tube to the designed radius.

Press Brake

A Press Brake is a piece of manufacturing equipment that is used to bend sheet metal. This process is largely used at our BA2 Workshop where we produce our aluminium systems, perforated screens, and Balustrade fascia’s. A Press Brake is typically narrow and long so that large pieces of sheet metal can be bent. It bends sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die.

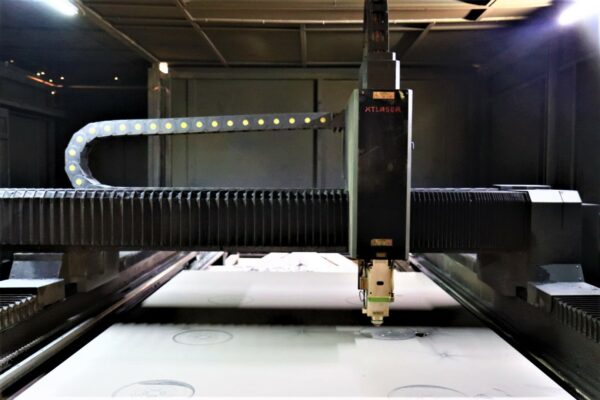

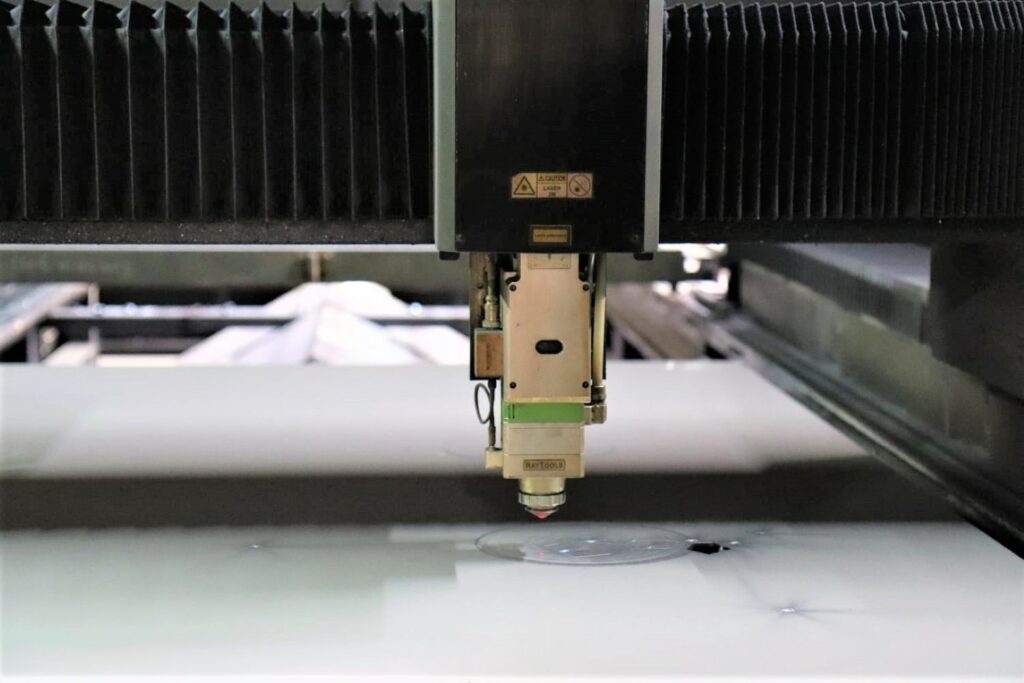

Laser Cutting

Laser Cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas,[1] leaving an edge with a high-quality surface finish.[2]

Recent investment in this machine has come with many advantages including providing more accurate lead times with no need to replace or modify tooling. These are highlighted further in this article here

We also carry out a variety of other smaller processes across our entire fabrication journey, such as various drilling processes and other processes that assist at the product assembly stage. Our recent investments in new equipment have allowed us to quote on shortened lead times, giving confidence to our customers that we will deliver in time and to the highest standard as we’re in closer control of what we’re producing.

To find out more about our process, you can read about it here

BA Systems provides a full and comprehensive design, manufacture and install service of our balustrade and handrail products and systems.

Find out more about us on this link here or contact one our technical consultants for no-obligation advice on how to correctly specify balustrade systems for a wide variety of sectors and applications.