The below outlines the different causes of ‘spontaneous’ glass breakage in order of likelihood (ref Guardian Glass, technical advisory note 011):

1. Impact Damage

This is the most common cause of ‘spontaneous’ breakage and can be both accidental or deliberate (e.g. throwing a stone). This cause is difficult to identify because the breakage pattern is often concealed by the fact that the glass can fall away from the frame on impact.

MITIGATION MEASURE – This is difficult to mitigate because it often occurs after the balustrade is installed. However, by specifying a handrail (even a small 30x30mm capping on a frameless glass balustrade), it can ensure there is at least a small horizontal barrier in place if the panel breaks. If the glass is laminated and depending on the system used, the horizontal handrail may also help to keep the panel in place until the glass can be replaced.

2. Edge Damage

Edge damage usually occurs when the glass is installed, outside the control of the factory environment. Mostly the glass breaks immediately, but occasionally there will be a delayed fracture of the glass. Although delayed fracture is very rare, an edge impact or chip can be present for up to a few months from the point of impact before the glass will destabilise and crack.

MITIGATION MEASURE: This can be mitigated by ensuring that installation is carried out by reputable and experienced installation operatives that have the correct glass handling equipment. It is also important that a quality control process is undertaken following the install of the glass to ensure that there is not any damage to the panels.

3. Poor Glazing

Most balustrade systems are designed to ensure that there are no stress concentrations on the glass and that loads are evenly distributed. However, poor installation or later additions to the barrier can cause undue stress on the glass. Over time this can cause the glass to weaken and then fracture.

MITIGATION MEASURE: It is important that glass balustrades utilise tried and tested balustrade systems that have been proven to meet British Standards. For example, the load on the laminated glass in a frameless balustrade channel system must be evenly distributed across the width of the panel to ensure there is not any undue stress on the glass panel.

4. Bad Design

If the balustrade has been designed incorrectly then this can cause wear and tear on the glass. Over time this can cause the panel to weaken and the glass to spontaneously break. Examples include, if the tolerances are too tight on bolted connections or if there are protruding fixings rubbing against the glass.

MITIGATION MEASURE: This glass breakage cause is similar to poor glazing and the mitigation measures also are very similar. It can also be mitigated through project-specific surveys and design to ensure that standard systems suit specific details and dimensions. Generic calculations and design validate the overall system, however project-specific design provides assurance that the manufactured product is very accurately suited to the project.

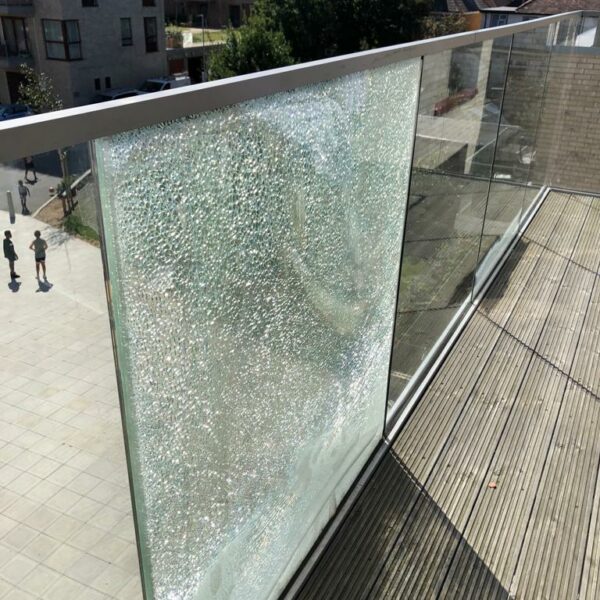

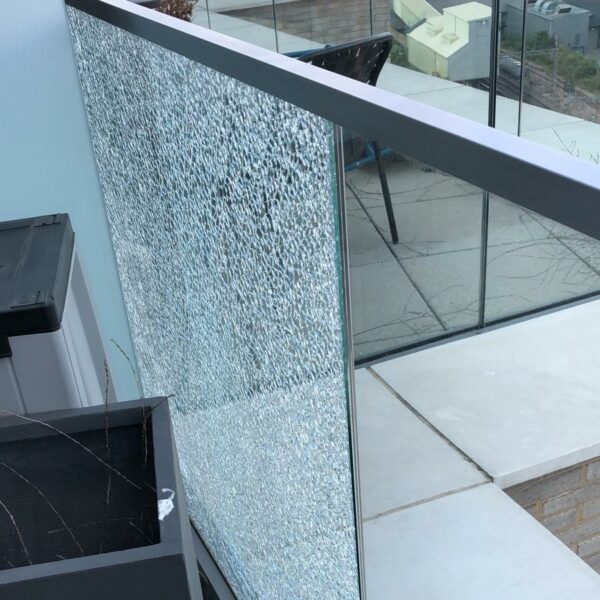

5. Foreign Particles

There are several foreign particles or impurities in toughened glass that can cause ‘spontaneous fracture’. Nickel Sulphide (NiS) is the most common. It is caused during the toughening process where glass is heated up to more than 600°C, then is rapidly cooled. The NiS is then ‘frozen’ into the glass. If the NiS is in the central zone of the glass, as it expands over time or during heat waves it can cause the glass to break.

Due to the size of the impurity and the infrequency of its occurrence, it is extremely difficult to detect at manufacture stage.

MITIGATION MEASURE: There is 2 key mitigation measures that can be taken:

1) Ensure that glass can be sourced back to a reputable manufacturer. Sulphur in the NiS is unavoidable. However, nickel can be reduced through careful controls in the manufacturing process. There is clear evidence to suggest some key manufacturers, such as Guardian Glass, have taken very effective steps to control this process. However, this is not the case for all foreign glass suppliers.

2) Specify the heat soaking of toughened glass. This process heats the glass to 290°C then is left for a period where a large percentage of the contaminated panels will break prior to dispatch.

BA Systems provides a full and comprehensive design, manufacture and install service of our balustrade and handrail products and systems.

Find out more about us on this link here or contact one our technical consultants for no-obligation advice on how to correctly specify glass balustrade systems for a wide variety of sectors and applications.