MANUFACTURING PROCESS

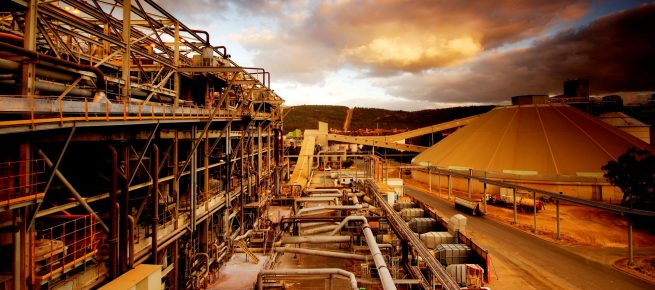

1. Bauxite Mining

Bauxite is used as the main raw material in the manufacture of aluminium. It is a clay mineral found in tropical and sub-tropical areas such as Australia and the West Indies.

The bauxite is often mined from only a few metres below the ground level. About 4-5 tonnes of bauxites are required for 1 tonne of aluminium.

To extract pure alumina, the Bayer process is used.

2. Bauxite grinding

The bauxite mineral is transported to refineries where the clay is washed off and the bauxite passes through a grinder to produce a more consistent material.

3. Bauxite crushing and digesting – producing sodium aluminate

The ground mineral is pumped into large pressure tanks with a caustic soda or sodium hydroxide solution, and a steam heat is applied. The caustic soda reacts with the aluminium compounds in the bauxite material to produce a solution of sodium aluminate (also known as slurry). The unwanted residues (also known as red mud), containing iron, silicon and titanium, gradually sink to the bottom of the tank and are removed.

4. Settling

The sodium aluminate solution is then passed through into lower pressure settling tanks. The solution at the top of the tanks is directed downwards through a series of filers to remove excess red mud. The remaining alumina is then passed through huge “leaves” or cloth filters to remove any solids in the solution.

5. Precipitation

The sodium aluminate solution is then cooled and pumped into large precipitators (sometimes as tall as a 6-story building). Aluminium hydroxide seed crystals added to the solution to start the precipitation process. At this point, large aluminium crystals are formed.

6. Calcination

The crystals are then heated in rotary kilns to temperatures over 960°C. This extracts the last impurities and creates a white powder, known as alumina or aluminium oxide.

The refined alumina is transformed into aluminium through the smelting or Hall–Héroult process.

7. Smelting process

The alumina is poured into a reduction cell with 950°C molten cryolite. 400kA electrical currents are passed through the mixture to break the bond between the aluminium and oxygen. The result is 99.8% pure aluminium.

.

MAKING ALUMINIUM USEFUL

Pure aluminium has limited uses, and the material has to be alloyed to increase its strength.

Common alloys include the 6000 series which is formed with magnesium silicide to create a corrosion resistant, strong and machinable material.

The liquid aluminium is then processed in three methods:

Extrusion:

This is a widely used method to create a fixed cross-sectional profile. The aluminium alloy ingot is heated up to 350-500°C, and then pushed by a hydraulic press through the die. The material is then cooled and stretched to relieve any stress. This versatile process is used to create many of the BA Systems balustrade products, such as the B40 Frameless Balustrade base ICE channel (fig. 2).

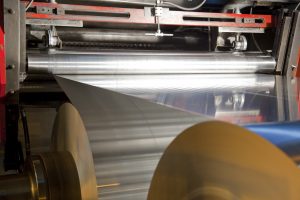

Rolling:

The aluminium alloy is cast into large rectangular beams, up to 9 metres in length. The malleable aluminium beams can then be rolled into thin sheets. This used for beverage cans and foil and can be rolled as thin as 0.006 mm.

Foundry alloys:

This can be achieved through cold-chamber casting. The metal is heated up in a furnace and then fed into the die with a hydraulic piston. The die will then shape the aluminium to its required form. This is a process used for many applications, such as in the aerospace and electronics industries.

.

RECYCLING

Recycling scrap aluminium requires only 5% of the energy used to make new aluminium. Aluminium can be recycled over and over again without it losing any of its natural qualities.

Recycled aluminium is sorted, cleansed and remelted to form molten aluminium. The molten aluminum is then formed into ingots for rolling, casting or extruding.

Due to the strength, versatility and lightweight properties of aluminium, BA Systems use the material extensively. It is used for small trims to integrate with our balustrade fixing details, handrail capping, base channel, channel trims and other applications. Contact the team to find out how they can work with you to make it suit your requirements.

Back to blog